Roll forming is a process that shapes flat metal sheets into continuous profiles using rolling operations. It’s energy-efficient, cost-effective, and ideal for high-volume production, offering tight tolerances and smooth surface finishes. Unlike forging or extrusion, it operates at room temperature for faster results.

How Custom Metal Roll Forming Works

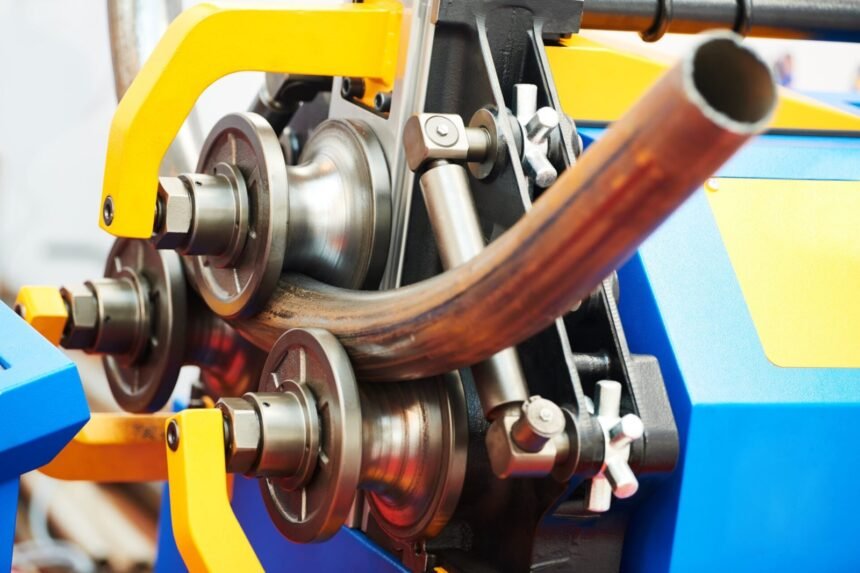

The roll forming process guides metal strip through consecutive sets of rolls, each pair progressively bending the material closer to its final shape. Each station performs a specific forming operation, gradually transforming the flat stock into complex cross-sectional profiles without compromising material integrity.

Tooling design represents the heart of successful roll forming operations. Engineers must calculate precise bend angles, radii, and spacing to prevent material distortion or splitting. The roll sets, typically mounted in a flender gear box system, maintain exact positioning and synchronized rotation speeds throughout the forming sequence.

Material selection plays an equally critical role in process success. The metal’s thickness, yield strength, and formability characteristics determine feasible bend radii, forming speeds, and the number of stations required. Proper material preparation, including surface treatments and edge conditioning, ensures consistent results and extends tooling life.

The forming sequence follows strict engineering principles. Each station performs incremental bends, typically between 10-15 degrees, allowing the material to flow naturally without work hardening or cracking. This gradual approach enables the production of complex shapes that would be impossible through single-step forming methods.

Materials for Roll Forming Applications

Steel dominates roll forming applications due to its excellent formability and strength characteristics. Cold-rolled steel offers superior surface finish and dimensional accuracy, making it ideal for visible components. Hot-rolled steel provides cost advantages for structural applications where surface appearance is secondary to strength requirements.

Aluminum brings unique advantages to roll forming operations. Its lightweight properties and corrosion resistance make it popular in aerospace and automotive applications. The material’s excellent thermal conductivity also benefits in applications requiring heat dissipation. However, aluminum’s tendency to work-harden requires careful attention to forming sequences and tooling design.

Stainless steel combines corrosion resistance with mechanical strength, making it valuable for food processing, medical, and marine applications. Its higher forming forces and spring-back characteristics demand specialized tooling approaches, but the resulting parts offer exceptional durability and appearance.

Copper and brass serve specialized markets requiring electrical conductivity or decorative finishes. These materials form easily but require careful handling to prevent surface marking during the rolling process.

High-strength steels present unique challenges and opportunities. While they demand more sophisticated tooling and process control, they enable lighter-weight designs with superior mechanical properties. Advanced high-strength steels used in automotive applications demonstrate roll forming’s capability to handle demanding material specifications.

Industry Applications

The automotive sector relies heavily on roll-formed components for structural elements, trim pieces, and functional hardware. Door frames, window channels, and reinforcement members showcase the process’s ability to create lightweight yet strong components. Recent trends toward electric vehicles have increased demand for battery enclosure components and specialized brackets requiring precise dimensional control.

Construction applications span from structural members to architectural details. Metal roofing and siding profiles represent high-volume applications where consistency and weather resistance are paramount. Specialty applications include trailer flooring support systems, where the process creates custom cross-sections optimized for load distribution and weight reduction.

The aerospace industry demands exceptional precision and material consistency from roll-formed parts. Aircraft interior components, structural brackets, and specialized fastening systems demonstrate the process’s capability to meet stringent quality requirements while maintaining cost competitiveness.

Electronics manufacturing utilizes roll forming for heat sinks, equipment enclosures, and component mounting systems. The process’s ability to incorporate holes, notches, and other features during forming eliminates secondary operations while maintaining precise positioning tolerances.

Agricultural equipment manufacturers depend on roll forming for implement frames, conveyor components, and specialized attachments. The process’s flexibility allows rapid adaptation to new crop requirements and farming techniques without significant tooling investments.

Benefits of Custom Roll Forming Solutions

Custom roll forming dramatically reduces material waste compared to stamping operations. The continuous nature of the process eliminates the scrap typically associated with blanking operations, often achieving material utilization rates exceeding 95%. This efficiency becomes particularly valuable when working with expensive specialty alloys or when environmental considerations drive sustainability initiatives.

Precision capabilities of modern roll forming systems rival those of machined components at a fraction of the cost. Computer-controlled systems maintain dimensional tolerances within ±0.005 inches across complex profiles while operating at production speeds measured in hundreds of feet per minute. This combination of precision and speed makes custom roll forming ideal for high-volume applications requiring consistent quality.

Cost effectiveness emerges from multiple factors beyond raw material savings. The elimination of secondary operations, reduced handling requirements, and minimal tooling maintenance contribute to lower total production costs. Custom tooling investments typically recover within months of production startup, after which the ongoing cost advantages compound over the product lifecycle.

Design flexibility allows engineers to optimize part geometry for specific performance requirements rather than accepting compromises imposed by alternative manufacturing methods. Features like strengthening ribs, mounting tabs, and service access holes can be incorporated during forming, eliminating assembly operations while improving overall product performance.

Future Innovations in Roll Forming

Advanced process monitoring systems now provide real-time feedback on critical forming parameters. Sensors monitor roll forces, strip position, and dimensional characteristics, enabling immediate corrections before defective parts are produced. This technology reduces startup waste and improves overall equipment effectiveness.

Simulation software continues advancing roll forming process development. Modern programs predict material flow, stress distribution, and potential defects before tooling fabrication begins. This capability reduces development time and tooling iterations while improving final part quality.

Adaptive control systems represent the next frontier in roll forming automation. These systems automatically adjust forming parameters based on incoming material variations, environmental conditions, and real-time quality measurements. The result is consistent part quality despite normal manufacturing variations.

Integration with Industry 4.0 concepts enables predictive maintenance, quality tracking, and production optimization across entire manufacturing systems. Connected roll forming lines communicate with upstream and downstream processes, optimizing overall production flow while maintaining detailed quality records.

Conclusion

Custom metal roll forming offers precision, efficiency, and cost-effectiveness, making it a key technology in modern manufacturing. As industries evolve and demand higher quality at lower costs, roll forming remains a reliable solution for creating complex components. Explore how it can enhance your next project.