In today’s electronics industry, smarter products begin with smarter manufacturing — and that foundation is built on advanced processes such as SMT and the capabilities of a reliable PCB assembly manufacturer. As product lifecycles shorten and performance requirements rise, companies need a manufacturing partner that offers not just assembly, but a full-stack, data-driven ecosystem that ensures speed, precision, and long-term reliability. That’s where PCBasic stands out.

- Full-Stack Manufacturing: From Concept to Complete Electronics

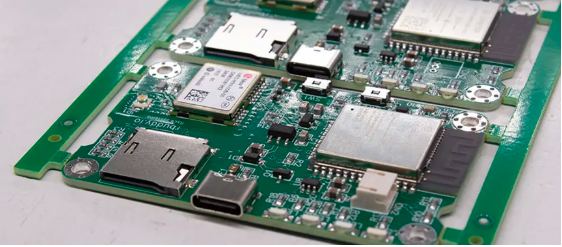

PCBasic provides a complete end-to-end electronic manufacturing solution, combining PCB fabrication, SMT assembly, DIP assembly, testing, and box-build into one unified workflow.

This integrated model eliminates communication gaps, reduces lead time, and ensures that every stage — from bare board to finished module — follows the same quality logic.

What “Full-Stack” Means in Practice

- PCB design support and manufacturability review

- Multi-layer PCB fabrication with precision controls

- High-speed SMT line for micro-components (01005/0201)

- DIP wave soldering & selective soldering

- Quality inspection (SPI, AOI, X-ray, ICT, FCT)

- Box-build and functional module integration

- Packaging & logistics with full traceability

This ensures a smooth process and predictable manufacturing quality.

- Smart Manufacturing Powered by Data and Automation

PCBasic’s smart factory is built on digital infrastructure, creating a closed-loop quality and production management environment.

Key Smart Features

- MES real-time monitoring: Every board, reel, and process is traceable.

- Automated inspection: SPI + AOI + X-ray detect defects before they reach final assembly.

- Predictive quality analytics: Data-driven insight reduces rework and improves yield.

- Automated material management: Barcode + ERP integration prevents mix-ups and shortages.

This level of automation ensures consistent production even in high-mix, high-reliability projects.

- High-Reliability Manufacturing for Critical Industries

PCBasic specializes in sectors that demand long-term stability and strict compliance:

Industries Served

- Industrial control

- Medical devices

- Automotive electronics

- Communication systems

- IoT and consumer electronics

- Renewable energy and power applications

PCBasic follows global standards including ISO 9001, ISO 13485, IATF 16949, and IPC Class 3 manufacturing guidelines.

- Advanced Testing Ensures Smarter, Safer Products

Testing isn’t an optional add-on — it’s the foundation of reliability. PCBasic builds testing into every stage of the workflow.

Testing Capabilities

- Solder paste SPI

- AOI + X-ray inspection

- In-circuit testing (ICT)

- Functional testing (FCT)

- Aging & thermal cycling

- Environmental simulation tests

By verifying every step, PCBasic ensures each PCBA performs reliably in real-world scenarios.

- Box-Build & System Integration for Faster Market Launches

PCBasic offers final enclosure assembly and system-level integration, helping customers shorten development cycles and reduce supply-chain complexity.

What Box-Build Includes

- Wiring harness assembly

- Mechanical assembly

- Firmware loading & calibration

- Complete product-level testing

This end-to-end approach means customers receive a production-ready device, not just a board.

Conclusion: Smart Manufacturing for the Next Generation of Electronics

Modern electronics need more than basic assembly — they need precision, traceability, automation, and long-term reliability. PCBasic’s full-stack electronics solutions combine smart manufacturing, advanced equipment, and strict quality control to help companies build smarter, safer, and more competitive products.

Whether you need rapid prototyping or mass production, PCBasic delivers manufacturing intelligence that transforms your ideas into reliable electronic solutions.