Figure1: Precision CNC turning ensures rapid prototyping accuracy and cost control, leveraging advanced machinery and expert oversight.

Introduction

In the world of Rapid Prototyping and manufacturing to order, there are triple threats that many engineers and project managers face: delayed deliveries, cost overruns, and non-conforming parts. Many of these problems usually have an identifiable root cause: poor choices when choosing a CNC Turning Supplier. Projects are set back all too often without a structured method for evaluating suppliers.

The following selection guide uses international standards, such as ISO 9001, as its base to provide a missing link between design intent and manufacturing execution, making sure a project is both on time and within budget.

Why is precision CNC turning necessary for rapid prototyping projects?

The essence of Rapid Prototyping is not about speed, but rather fundamentally about accuracy and validation. A prototype that isn’t correct for the intended final product will result in flawed testing, incorrect design assumptions, and costly revisions downstream. It is here that the principles of Precision Engineering become critical.

By applying Precision CNC Turning, projects are able to achieve high tolerances and superior surface finishes, which are needed for functional testing and verification of form-and-fit.The exacting standards from the beginning cannot be overemphasized. Standards such as ASME Y14.5 Dimensioning & Tolerancing offer a common language when it comes to design specification communication.

Applying such standards at the level of prototyping, through precision machining, ensures that geometric tolerances are interpreted and manufactured correctly. This rigorous approach diminishes the chances of propagating possible design flaws into production, where corrections become exponentially more expensive. In essence, Precision CNC Turning is not an indulgence but a necessity in creating prototypes that are representative and reliable.

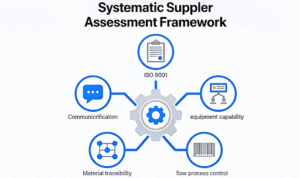

Figure2: A structured framework based on international standards helps systematically assess CNC suppliers to mitigate project risks.

How to Evaluate Quality Commitments for Custom Parts in On-Demand Manufacturing?

What the On-Demand Manufacturing model requires from the supply chain is agility with consistent quality. Assessing a potential supplier’s commitment to quality has to be multi-dimensional in nature, particularly for mission-critical Custom Parts.

Four Pillars of Supplier Assessment

A sturdy evaluation would be based on four key pillars: quality systems, capability of equipment, material certification, and process control.

-

Quality Systems and Certifications

A verifiable QMS forms the basis for a reliable supplier. Certification to ISO 9001:2015 is one of the primary indications the supplier has instituted processes that are systematic, assuring quality and continuous improvement. In industries like automotive or aerospace, there are necessary certifications such as IATF 16949 or AS9100D respectively.

-

Technical Capability and Process Control

Aside from paperwork, one must delve into a supplier’s technical capability: age and capability of CNC machinery, availability of state-of-the-art metrology equipment such as CMMs, and skill level of the programming and engineering staff. Strong process control means that lots of parts produced are consistent in quality.

From Industrial Design to Physical Part – What is your CNC service selection guide?

Translation of an Industrial Design into a quality physical component involves a structured process for vendor selection. An elaborate CNC Service Selection Guide involves critical steps that start from the design review to production kick-off.This begins with a thorough DFM analysis. A capable supplier will offer unsolicited input to optimize the design for machining, which can greatly lower costs while improving lead times. While reviewing a CNC Turning Quote, the key elements to be reviewed lie beyond the bottom line.

These include tolerance standards, material specifications, surface finish requirements, and inspection protocols. Also very relevant is clear communication about production capacity and scheduling to avoid bottlenecks. Besides, in this process, LS Manufacturing can also extend collaborative value as a professional service provider by acting as a manufacturing partner rather than just a vendor. Refining designs and anticipating such production challenges depends on the engineering team.

5 Critical Questions to Clarify When Requesting a CNC Turning Quote

A CNC turning quote should have more to say about a roadmap to partnership than a price list. Asking the right questions can make the quoting process a strategic assessment. These questions can be broadly categorized into two levels, which are technical capability and project management.

Assessment of Technical Capabilities and Quality Assurance

Basic questions look at the ability of the supplier to meet consistently the technical specification of the part.

-

Interpretation of Tolerance and Methods of Inspection

It is critical to establish with clarity how the supplier interprets the drawing’s tolerances and what their equipment is capable of reliably producing. Reference to standards, like ASME Y14.5 ensures a common understanding. The response should include their standard tolerances for the turned parts and what kind of inspection equipment, such as CMMs, are put to use in checking those tolerances.

-

Material verification and traceability

There is a non-negotiable requirement for full material traceability on critical Custom Parts. The supplier shall identify what type of certification is supplied, such as mill certifications, and how they ensure the authenticity of materials through to the final production of parts.

Those interested in how such selection is made can refer to this guide: How to Choose the Best CNC Turning Service.

Project Management and Commercial Terms Evaluation

Besides the technical specifications, it is the approach of the supplier to the execution of the project and commercial flexibility that will make the partnership succeed.

-

Pricing – Scalability & Structure

The cost scaling from prototype to low-volume and mass production is of great importance for long-term project budgeting. The supplier must clearly define his pricing structure, able to show the economies of scale, pointing out potential cost drivers.

-

Communication of Risks and Timelines

A proactive supplier will have a clear communication plan. The response must detail when and how they communicate potential project risks, delays, or other issues. This is important with regards to the management of project timelines and informed decisions.

The Best CNC Turning Service – A Definition Beyond Price

The Best CNC Turning Service is defined by a synergy of the many factors put together to create value well over and above what a competitive unit price can offer. Technical capability, quality consistency, and excellent service-these elements are part of true excellence.

Of course, technical capability in Precision CNC Turning is a pre-requisite, but should be supported by a quality system such as ISO 9001 for consistency. Transparency of communication and project management engenders trust. Increasingly, another differentiator is a commitment to sustainability, represented by certifications such as ISO 14001. What this means for the On-Demand Manufacturing context is that the ideal CNC Turning Supplier is one that is robust, reliable, and able to flex with demand requirements without yielding any ground on quality. The value they bring is the reduction of total project risk while speeding up time-to-market.

Conclusion

The choice of the right CNC Turning Service is a strategic one and linked directly to the success of any Rapid Prototyping and On-Demand Manufacturing program. Using such an organized method to evaluate technical proficiency, quality system elements, and collaborative capability helps a company avoid common missteps related to budget blowouts and delays.

This document is best utilized by re-assessing existing lists of active suppliers, or by asking that detailed capability documentation be provided by potential partners, utilizing the ISO 9001 and AS9100D standards.

About the Author

The author of this article is a senior manufacturing expert with 15 years of experience in precision machining. He focuses on solving the most challenging problems faced by clients in the aerospace, medical device, and other industries in the development of complex part prototypes—how to reduce delivery cycles by 30% while maintaining tolerances of ±0.005mm. Based on a deep understanding of ASME Y14.5 and ISO 9001 standards, he has successfully led the delivery of over 200 rapid prototyping projects with zero defects.

FAQs

Q: What kind of customized parts are best suited for CNC Turning?

A: CNC turning could be quite useful in manufacturing parts of rotational symmetry, for example shafts, bushings, flanges, threaded components, among others, but in particular those from metals or plastics.

Q: What information is needed when inquiring about a CNC turning quote?

A: Key information to include in your RFQ includes detailed 2D drawings or 3D models with tolerances, material type, surface finish, quantity, and target lead time.

Q: What does ISO 9001 Certification Signal for a CNC Turning Supplier?

A: It means that the supplier has a documented quality management system for consistent supply of products meeting customer and regulatory requirements, and also has a format for focusing on continual improvement.

Q: In a Rapid Prototyping project, which is more important: lead time or quality?

A: Both are of equal importance. The objective is to identify a supplier that can provide conforming parts within the necessary time scale. If quality is sacrificed then prototype is not useful for validation and causes greater project delays/costs.

Q: How can a supplier’s Precision CNC Turning capability be evaluated?

A: Assessment would include machine tool precision evaluation, such as repeatability; inspection equipment, such as CMMs; understanding of the engineering team about standards such as ASME Y14.5; and review of case studies similar to the Precision Engineering projects.