If you’re exploring a diffractive beam splitter, you probably want precision. You want predictable performance. Maybe you are building a laser system, doing imaging, or working in metrology. The term might sound technical. But choosing the right one can make or break your whole project.

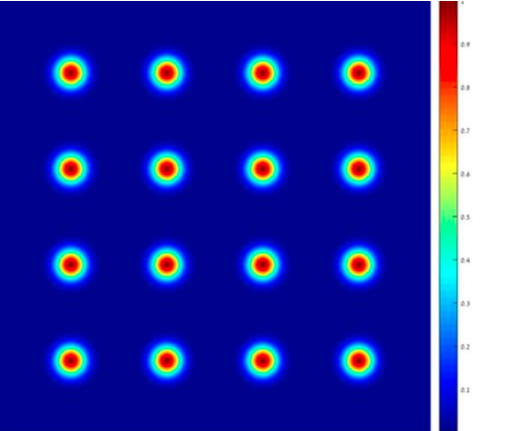

A diffractive beam splitter is an optical element that takes one input beam and divides it into multiple output beams. Each output can have the same size, divergence, intensity shape, etc., if done well. But only if the design and manufacturing are top-notch.

What Makes a Great Diffractive Beam Splitter

Here are the real, critical aspects people with real demands always check first:

- Efficiency at the design wavelength

These splitters need to be designed for a specific laser wavelength. A small shift (1–2%) is usually okay. But stray too far and efficiency drops, and angles of output beams shift. High-ranked data says good ones still maintain over 80-90% diffraction efficiency in many designs. (Wavelength-OE)

- Uniformity and low zero-order beam

When you split a beam into many spots, you want them to be even — same brightness, same shape. And you want the zero-order (undiffracted light) to be very small. If that zero-order is high, it steals power, adds noise, reduces performance. Top splitters achieve zero-order values of <0.5-1% of input. (Wavelength-OE)

- Pattern flexibility

Do you need a 1×N array, a 2D matrix, or maybe a custom layout (e.g. hexagonal, random dot)? The best designs let you choose the pattern. You don’t want a module that locks you into one layout. (Holo/Or)

- Material & handling of power/heat

Laser power heats things. Some materials survive better. Coatings matter. The optical substrate (glass, fused silica, etc.) should resist deformation under heat and stay stable under high power. If you push without attention to this, performance drifts. (Wavelength-OE)

- Ease of integration

A good diffractive beam splitter should slot into your optical setup without endless tinkering. Alignment tolerances, mounting features, mechanical stability—all of this matters. If the mounting is tricky, or the tolerance too tight, you spend hours just setting things up. Top-rated pages emphasize manufacturable tolerances (tilt, tip, working distance) that still give good output. (Holo/Or)

Where People Use These Splitters, And What’s Expected

Knowing where diffractive beam splitters excel helps you understand what you should demand:

- Medical / aesthetic lasers – fractional laser treatments often use multispot splitters. You need clean spots, even power between spots, and stable performance over repeated use. (Holo/Or)

- Material processing & industrial laser work – splitting beams to increase throughput. E.g. cutting, welding, or engraving with multiple spots. You want high efficiency, durability, very low distortion. (Holo/Or)

- Quantum optics / scientific / metrology – sometimes need large arrays of spots for quantum dot excitation, or parallel readout. There, specs like spot uniformity, wavelength specificity, and stability under environmental change are critical. (Holo/Or)

How Top Sources Advise You to Judge Specs

From reviewing several leading datasheets and technical articles:

- If a spec sheet says “efficiency ~75-85%” that’s decent for many applications. But if it promises ≥95%, expect multilevel or complex DOE manufacturing. Wavelength Opto-Electronic Singapore.

- Uniformity measures are often <1-3% variation between spots. If specs say “good” but don’t give numbers, that’s suspicious.

- Zero-order energy should be quantified. Either in absolute % of input, or relative to other orders. If the manufacturer doesn’t show it, ask.

- Operating wavelength tolerance: +/-2% is commonly acceptable. If you operate far off the design wavelength, performance falls fast.

- Working distance & beam size requirements: you’ll see recommendations like “minimum beam size = 3× DOE period” for certain patterns. If your beam is too small, spots overlap or distort. Holo Or+1

What Could Go Wrong If You Don’t Check Carefully

I’ve seen cases where engineers choose a diffractive beam splitter that looked “cheap enough,” only to struggle later:

- Spots are uneven, some too bright, some dim. Causes data errors.

- Efficiency very low → they need more laser power → heat problems or lifespan issues.

- Zero-order light strong → unwanted background, interference.

- Module misaligned → pattern distortions, reduced resolution.

These are not just annoyances. They cost time, money, reputation.

Final Advice

If you’re selecting a diffractive beam splitter, do this:

- Define your exact needs: pattern layout, power, operating wavelength, environmental conditions.

- Ask manufacturers for full specs: efficiency, uniformity, zero-order, tolerance data.

- Test early, if possible. Use the splitter in real conditions that match your end-use.

- Favor designs with good in-house control over design, simulation, and fabrication (pattern/DOE expertise).

Choose not for lowest price. Choose for reliability. Because when a diffractive beam splitter performs, everything downstream is easier.

FAQs:

Will the spots stay even when we increase laser power or run for hours?

Yes, that’s a valid concern. Many designs degrade under heat or wear. But the high-quality splitters use substrates and coatings rated for power, and maintain uniformity even under prolonged use. Ask to see those validation tests.

What if I need the beam splitter to work at slightly different wavelengths later on?

It can be tricky. DOEs are usually optimized for one nominal wavelength. Deviation of even a few percent can shift angles or reduce efficiency. If you expect variation, buy a design with tolerance or choose multilevel DOEs with broader bandwidth.

How can I avoid surprise costs after I install the splitter?

Many surprises come from hidden specs: poor zero-order control, need for custom mounting, or needing extra lenses to focus the pattern. If you ask good questions — “what’s the zero-order %?”, “what’s the minimum beam size?”, “what are alignment tolerances?” — you’ll avoid most surprises.