Do you know how fuel is delivered to the engine in your car? The car fuel system is responsible for this, where different individual components work together to deliver fuel to the engine. Further, combustion powers the engine and runs the wheel.

Any technical issue or low quality of the fuel system components directly impacts the performance and mileage of the vehicle. Furthermore, any immediate leakage or issue in the fuel can ignite the fire, leading to a potential accident or hazards. Therefore, car manufacturers rely on precise and accurate best CNC machining services to manufacture the fuel system parts.

Continue reading, this article will further cover what a car fuel system is, types of fuel injection, machining of fuel components, and other various aspects.

What is a Car Fuel System?

It is a sensitive system in a car that involves the fuel tank, pump, fuel line, filter, and carburetor. Combinedly, they deliver the fuel to the engine as needed. It does everything once you fill the tank; this system ensures a smooth supply of gasoline and eventually powers your vehicle. At the same time, any fault in the system can disrupt the performance.

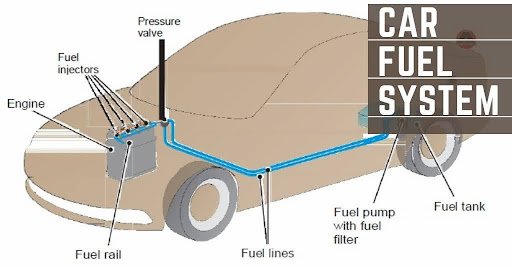

The car fuel system diagram below outlines the involved components and their workflow.

Fuel system diagram

- Fuel Tank: A gasoline or diesel tank made from high-density plastics or steel alloys. It stores the fuel and also accommodates a fuel pump inside.

- Fuel filter: It removes any contamination particles, rust, dirt, etc.

- Feed Line: Also called car fuel lines, it carries the pumped fuel further. These delivery lines are made from corrosion-resistant materials like steel, aluminum, PTFE, and Nylon.

- Injectors: Injectors spray the fuel into the intake manifold (or engine chamber) via a nozzle. An electronic device called the engine control unit (ECU) controls the spraying interval and pattern.

- Pressure Regulator: This component regulates the injection pressure with respect to the combustion chamber’s demand.

- Ignition Switch: Once the ignition switch turns on, it activates the solenoid relay and starts the fuel pump, allowing the fire to be ignited in the chamber at the right time.

Types of Fuel Injection Systems

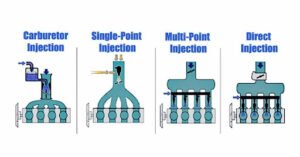

Types of fuel injection

There are different types of fuel injection systems, each with a distinct mechanism and characteristics, such as throttle body injection, direct fuel injection, and port fuel injection.

Let’s elaborate in brief;

- Carburators

A carburetor is a traditional automotive fuel system, in which throttle valves regulate the mixture and nozzles send the fuel to the intake manifold. A float controls the volume of fuel droplets and air entering the engine. Due to high emissions, most of the automotive companies do not use this type of injection system in modern cars.

- Throttle Body Injection

This injection system mixes the fuel and air in the throttle body, whereas the ECU controls the injector pulse width to deliver the desired input to the engine. The throttle body fuel injection system was primarily designed to replace the carburetor.

- Direct Fuel Injection

This is mainly used in a diesel engine, where the fuel pump delivers the diesel to the engine chamber, whereas the ECU controls the spray pattern and timing. The fuel is converted into droplets through pressure before leaving the nozzle.

- Port Fuel Injection

Unlike throttle body injection, this car fuel system delivers the fuel outside the intake manifold. Then, air mixes with the fuel there and goes into the chamber. It provides better performance and fuel efficiency.

How Automative Fule System Components Are Made?

Both plastic and metal components are needed for the automotive fuel system. Therefore, multiple techniques like blow molding, injection molding, CNC machining, and tube bending are used to produce them.

- Blow Molding

This method is mainly used to make HDPE Fuel storage tanks. It involves loading the mold cavity with molten plastic and blowing air from the centre to create a strong hollow structure.

- CNC Machining

CNC machining involves various machining processes, including milling, turning, drilling, threading, etc. This technology is favourable for making precise metal components in the fuel system, like injector nozzles, pump housing, and pressure regulators. It can deliver tolerance as precise as ±0.0025 mm.

- Tube Bending

The tube-bending process forms the fuel lines by bending metal tubes, such as steel and aluminum. However, the fuel lines are also made from plastic; in that case, blow or injection molding is favourable.

- Other Methods

Besides these other methods, like aluminum extrusion, injection molding, and sheet metal forming are also used, depending on the requirements.

Do you have a feeling that you need to order components from different suppliers due to the diversity of manufacturing methods? Don’t worry, on-demand manufacturers like ProleanTech can make all the different components inside a single workshop, even final assembly.

Common Fuel System Issues and Maintenance

Custom CNC-machined fuel nozzles.

Let’s look at the common issues that might occur in the car’s fuel system and their causes in the table below.

| Issue | Causes |

| The engine won’t start | Defect on the fuel pump, clogged fuel filter, and injector failure. |

| Hard starting | Weak pump, restricted fuel line, low fuel pressure, and regulator failure. |

| Engine stalling | Fuel pump overheating/failing, clogged filter, pressure regulator failure |

| Rough idle / misfire | Dirty or leaking injectors, ununiform fuel pressure |

| Poor fuel economy | Leaking injectors, regulator failure, and excess fuel delivery |

| Fuel odor & leakage | Cracked fuel line, leaking injector seals, damaged fuel rail, and pores on the fuel tank |

There are some tips on how you can minimize the issues discussed in the table through regular inspection and maintenance.

- Do not run your car at extremely low fuel levels, as it can cause issues with the fuel pump.

- According to your service manual, replace the fuel filter periodically.

- Regularly check components of gasoline fuel system and electrical connections to find out whether they are working correctly or no

- Inspect for faults and clogged injectors and replace them if they fail.

- Regularly inspect the fuel line for any corrosion, wear, or microcracks.

Conclusion

The fuel system is a critical component of a car, directly influencing the functionality, performance, and durability of the engine. This is composed of several individual parts assembled according to a particular fuel system design.

You must consider the correct manufacturing method and strict quality control measures to produce the fuel system component. Understanding various aspects of the fuel system helps to customize the system and achieve desired results, whether you are making it in your own shop or partnering with a secondary manufacturer.

FAQs

What is the fuel tank and how does it work?

It is a compact tank with a small opening at the top for fuel filling. This tank stores the fuel and acts as the intake of the fuel pump, which further delivers it to the engine.

How much does it cost to fix a car fuel system?

The cost depends on the diagnosed issue and the car model, from a few hundred dollars to a thousand dollars.

What are the symptoms of a bad fuel system?

The common symptoms of a bad fuel pump include hard starting, misfire, rough idling, poor fuel economy, and noise from the fuel system..

What does fuel system failure mean?

Fuel system failure means it can not deliver the desired amount of fuel to the engine due to any issue, such as a damaged fuel line, a clogged injector, a regulator malfunction, etc.

How does a car act when the fuel pump is going out?

It is difficult to start a car when the fuel pump goes out, as it can not provide enough pressure to pass the fuel further. Other symptoms could be car stalling, noise, and power loss.

How do you know if you need a fuel system service?

You can consider fuel system service if you are experiencing any issues in your fuel system or you need custom fuel systems.