There is a common and understandable confusion between CNC metal milling vs wood milling processes. While the fundamental technology is comparable, differences are evident in the type of cutting tool, precision levels, cutting technique, and material properties. CNC metal milling requires harder tools, higher precision levels, and the cutting process is usually slower.

To make the selection process simpler, especially for someone new to milling wood machine technology and CNC milling machines for metal projects, the next section of this article runs through several crucial comparison areas.

What Does A Milling Machine Do?

A milling machine equipped with computer numerical control (CNC) uses end mills, face mills, drills, and other tools to perform complex machining operations on materials.

This CNC machine that cuts wood and metal, along with plastics, polymers, and composites, can do several operations, including die sinking, contouring, keyway machining, drilling, and others.

What is CNC Metal Milling?

CNC metal milling is the automated process of removing material from a metal workpiece to create a predetermined part. The CNC programming process produces accurate and precise cuts in the material using carbide-tipped and other specialized tools.

Can You Do CNC Milling For Wood?

Yes, CNC milling wood is popular in architectural, boatbuilding, general woodworking, and furniture manufacturing. It generates desired product shapes, sizes, and surface finishes using different CNC milling tools and techniques.

Is Metal Milling Similar To The Wood Milling Process In Any Way?

Yes, there are fundamental characteristics shared by both metal milling and wood milling. The first point is that they are both subtractive manufacturing processes. A rotating multi-point cutting tool removes material from a part to achieve the final shape and dimensions.

Both methods are also very advanced thanks to Computer Numerical Control (CNC) technology. CNC metal and wood milling allow for the definition of precise cutting paths that the CNC machine automatically follows.

With the programming feature, the process can be custom-controlled to provide unique machining results.

A CNC program for milling

Setting up the machine is largely similar in both CNC metal milling and wood milling. The workpiece and CNC milling machine are prepared, the workpiece is securely placed on the machine, and then the process starts. In both instances, the correct machining parameters must be programmed in the machine.

While the specific cutting tools differ, the availability of a wide array of cutting tools is also a shared characteristic. Options include drills, end mills, and face mills.

The Main Differences Between CNC Metal Milling vs Wood Milling

When comparing metal milling and wood milling, the differences are seen in part precision, material properties, tooling requirements, and the cutting technique.

-

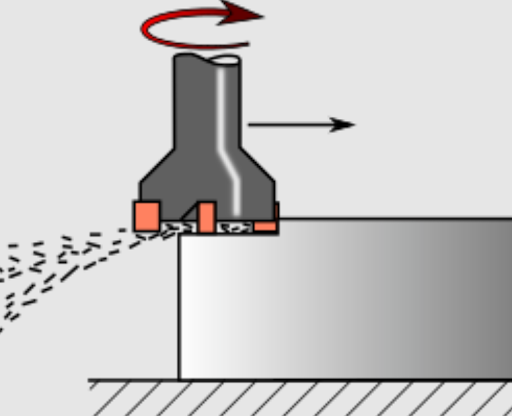

The Cutting Technique

The CNC metal milling process is relatively slower than wood milling, necessitated by the need to minimize tool wear and enhance cutting accuracy. Since wood is softer, the CNC wood milling process can be faster, provided tearing or burning issues are handled.

Regarding clamping and fixturing, metal workpieces are held more firmly because the cutting forces are much higher. Wood, a softer material, requires gentler clamping.

-

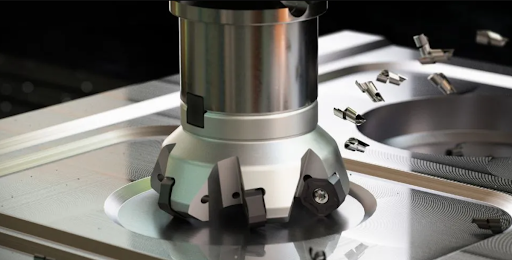

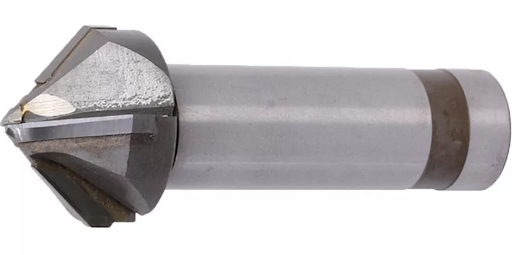

Tooling Requirements

Considering the difference in cutting forces mentioned above, a CNC milling machine metal uses harder tools tipped with ceramic or carbide material. Whether it is for end milling, face milling, or any other form of metal milling, a priority for the tools is often matching hardness.

A carbide-tipped milling tool

When it comes to wood milling, the process focuses on achieving a clean cut rather than the hardness of the material. High-speed steel tools are usually enough for these machining jobs.

-

Precision Levels

CNC metal milling is instrumental in aerospace, medical, and other high-stakes applications where precision and accuracy requirements are top-level. Therefore, a quality metal milling process must achieve precision of about ±0.001 inches (0.0254 mm), a far cry from the ±0.01 to 0.03 inches level that works for wood milling projects.

-

Material Properties

A lot can also be said about the metal and wood properties that guide the milling processes for each material. A glaring one is the grain structure, with the non-homogeneous nature of wood affecting the milling direction. A wrong milling approach results in splintering and tearing.

In CNC metal milling, grain structure is not a big concern because metals generally have homogeneous grain structures. The machining process is more predictable and manageable for metals.

How To Mill Small Metal Parts

Milling small metal parts requires high precision, tight tolerances, and minimal forces. Getting the fixturing right can be a challenge. To overcome such challenges, ProleanTech emphasizes the appropriate cutting tools, correct part design, and effective workholding.

What Are The Limitations/Disadvantages Of CNC milling?

Both CNC metal milling and wood milling have limitations. Here are a few to consider:

- Programming and machine setup errors

- The workpiece size limit is dependent on the milling machine

- Cannot generate complex internal shapes

- As a subtractive method, it can waste a lot of material

How Much Does It Cost to Get Something CNC Milled? What Are The Prices For CNC Milling?

The cost to CNC mill an item depends on factors such as the part’s complexity, geometry, and size, manufacturing volume, and supply chain reliability. Others are labor, client customization requirements, and market fluctuations.

For effective cost management of CNC-milled parts, consider ordering standardized parts, using cost-effective raw materials, applying batch manufacturing, and outsourcing strategically.

Conclusion

The above outline of the differences and similarities of CNC metal milling and wood milling shows that both processes are essential. The specifically designed application of each is the best way to determine which one to use, when.

CNC metal milling requires a more rigid setup, a characteristic that is evident in the CNC metal milling machines. For CNC wood milling, the machine is lighter and rotates much faster.

For more information on milling materials, be sure to check quality CNC machining services today.