Introduction

Amid the hardware startup boom, many innovative products fail or face major cost overruns not due to flawed ideas, but during the critical transition from prototype to mass production—where “the devil is in the details.” While teams excel in software and design, they often lack experience in precision production methods, cost structures, and supplier evaluation. Seemingly minor decisions in material selection, design tolerances, or order strategies can lead to significant cost increases or quality issues.

This article moves beyond basic vendor lists to analyze the three key stages—design verification, small-batch pilot production, and scaling up—clarifying objectives, cost levers, and partner selection at each phase. Understanding these different production needs is the first step toward informed decision-making and a successful product launch.

In general, what are the main differences between prototype and production with regards to manufacturing services needs?

Many hardware teams begin their frustration by making the basic mistake in specifications that manufacturing services have to meet for production versus prototype.

The main objective of the Rapid Prototyping stage is “verification.” Main requirements are speed and iterative flexibility when testing either fundamental functioning or confirming the look and feel of the Industrial Design. The benefit of prompt feedback and making adjustments has way greater value at this point than the unit cost, thus high tolerance for cost is required. Techniques could include small-batch CNC Machining Services, handcrafted examples, or 3D printing.

However, once manufacturing starts, the rules of the game change altogether. Ensuring consistency, reliability, and, ultimately, Precision Engineering quality in thousands or tens of thousands becomes paramount. Here, the paradigm of techniques such as Precision CNC Machining shifts from “making one” to “stably producing millions of identical ones.” Quality control procedures replicable, cost management, and supply chain stability also become paramount.

The belief that managing mass production with a prototyping mindset—pursuing last-minute design modifications, ignoring process stability, and comparing suppliers based only on unit price—is the exact reason why many projects fail. Because of this, communication with the CNC Machining Supplier is fundamentally misaligned. International quality management system standards such as ISO 9001, which provide a framework for process reliability and continuous improvement (something that is less emphasized in the prototyping stage of product development), are usually adopted by the best manufacturing partners to ensure consistency in production parts.

What are the unseen “cost assassins” in the design?

When an entrepreneur receives a CNC Machining Quote that is way more than expected, probably the problem is hidden in the details of the drawing. These design features are what is usually referred to as “cost assassins.”

The Underappreciated Price of “Complexity” and “Precision”

- Needlessly Tight Tolerances:

Tolerancing is the language of Precision Engineering, but overusing it increases costs. A non-critical fit’s tolerance might be tightened from ±0.1mm to ±0.01mm. This can increase the required machining time by a factor of two, requiring more accurate machinery and inspection tools, increasing the cost tenfold. To communicate design intent, tolerances should be specified on engineering drawings appropriately. The accurate quote relies on a mutual understanding of precision between supplier and designer, secured via authorized standards such as the American Society of Mechanical Engineers(ASME)Y14.5. - Difficult to Machine Internal Characteristics:

Deep holes with a high aspect ratio, interior sharp edges, tiny threads, or thin-walled features requiring special fixtures greatly increase the programming complexity, tool wear, and machining time. These factors increase the cost of Custom Parts.

Cost-Control through Proactive Design

Conducting Design for Manufacturability (DFM) is necessary for Custom Parts. Feedback about DFM should be provided by any respectable manufacturing service. A few Online CNC Machining Services offer quick price tools to do some preliminary design and cost simulation before formally requesting quotes. This instantly makes you sensitive about the relation between design aspects and costs.

How can a professional evaluate and select your manufacturing partner?

Similar to choosing a technical co-founder, choosing a manufacturing partner requires looking beyond “price comparison” and conducting a structured evaluation. The following dimensions should be part of a minimal set of the best CNC machining services guide.

Four Key Dimensions of Assessment

- Technical Capability and Equipment: Provide an analysis of their list of equipment to verify if it has the required precision tolerances and materials.

- Quality Control Procedures:Are they ISO 9001 or otherwise certified? Have they at their disposal modern examination tools?

- Flexibility in Production:Are small-batch and multi-batch On-Demand Manufacturing models supported?

- Communication Response:Will the engineers provide DFM guidance? Is the response timely and unambiguous?

Understanding “Total Cost of Ownership”

The lowest total cost is not equal to the lowest unit price. The consequence of delivery delays on the product launch window and quality failure risk cost should be assessed. A somewhat higher estimate from a supplier who ensures yield, meets deadlines, and provides reliable DFM often leads to a lower total cost of ownership.

From “Hearing” to “Verifying”

Be sure to request and carefully review case studies or examples of similar products they have machined. The most effective way is to place a small trial order to get started. You can refer to this professional guide for a more detailed description of How to Choose CNC Machining Services.

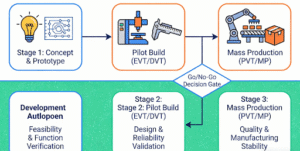

Figure2: A structured stage-gate process helps hardware startups manage risk and make informed decisions from prototyping to scale-up.

Figure2: A structured stage-gate process helps hardware startups manage risk and make informed decisions from prototyping to scale-up.

How should the transition be done smoothly from small batches to mass production in the strategy of manufacturing?

Manufacturing requires a very forward-thinking approach when the batches of hundreds turn into tens of thousands of pieces.

Precision CNC Machining has no molds and is very flexible. Therefore, during the stage of small batch trial production and market launch, precision CNC machining was still the best choice for making Custom Parts. On-Demand Manufacturing paradigm goes especially well with inventory risk management.

Volumes must be high, in the tens of thousands, before injection molding and other specialized tooling methods are justified. A seamless transition is important. Savvy teams seek out vendors with “bridge production” capabilities—partners that can handle medium-volume orders using CNC methods and also provide advice or services related to injection molding and mold making. This reduces the risks associated with switching suppliers.

What other value can high-end manufacturing service providers offer beyond machining?

The value of a top CNC Machining Supplier is much more than just running machine equipment. It is worth the expansion of its Precision Engineering capabilities:

- Early Design Involvement and Materials Science Advice:Providing insights into manufacturability at the concept stage.

- Supply Chain & Secondary Process Integration: Managing raw material procurement and integrating secondary processes like heat treatment and surface finishing.

- Simple Assembly and Quality Control: Performing component-level assembly and functional testing.

These value-added services can considerably fast-track time to market. For instance, the value of a full-service provider like LS Manufacturing lies in its tightly integrated services. International certifications by a manufacturing partner are clear indicators of the maturity of systems involved—particularly for strict supply chains like automotive (IATF 16949), aerospace (AS9100D), or those that strictly consider environmental management as per ISO 14001.

Conclusion

It takes creativity, engineering, and manufacturing know-how to transform a hardware product from a blueprint into a profitable commodity. Grasping the various manufacturing logics at each stage in the development process, proactively implementing Design for Manufacturability, and carefully assessing manufacturing partners will enable a startup to successfully circumvent major risks and put valuable resources to work on core innovation and market development.

The next best thing you could do, if you are at a critical point in the hardware development process and seeking a manufacturing partner who can truly understand your requirements from prototype to production and provide reliable precision engineering support, is in-depth examination of the full capability matrix of possible suppliers. Create your supplier evaluation checklist now.

About the Author

The author of this post is a specialist columnist in industrial technology, specializes in offering tech startups and SMEs useful solutions from product design to mass production, and has more than 10 years of expertise in supply chain management and precision manufacturing.

FAQs

Q1: Should I start with a CNC-machined prototype, or could I simply 3D print for preliminary concept validation?

A: High-accuracy 3D printing is faster and less expensive if only shape and fit need to be confirmed. If material strength, functionality, or thermal properties must be tested a prototype machined using a CNC and made from the production material yields results much closer to the production unit. The verification goal should form the foundation of the decision. Refer to Prototype Manufacturing for more detailed information on selecting prototypes.

Q2: How reliable is an online instant quote as compared to a physical quote?

A: Online quotes can quickly provide cost estimates and intuition and are suitable for simple, standard components. Manual quotes—coming with a DFM report—are more reliable for complex, high-precision, or items needing special processes because they include an authoritative evaluation of manufacturability given by an engineer.

Q3: How do I check the quality of a CNC machining shop?

A: You can also ask about the quality systems they follow, such as ISO 9001, the measuring tools they use, such as Coordinate Measuring Machine or CMM, and their quality inspection reports, such as First Article Inspection or FAI. The most direct approach is to ask for case studies or samples from projects they have completed that are similar to yours.

Q4: For what types of business is the “On-Demand Manufacturing” most suitable?

A: Especially fit for businesses with rapid product revisions, erratic demand, or low-inventory or zero-inventory operations; for startups, direct-to-consumers brands, and R&D facilities that need periodic replacement of fixtures or tools.

Q5: Why do some sophisticated part quotes have such a long lead time?

A: Besides machining time, lead time includes time required for process planning, ordering special tools, designing and making sophisticated fixtures, managing multiple processes, and rigorous quality control. Quality control and data validation, if necessary, may require much of the cycle time for precision products.