A Metal Core PCB (MCPCB) is a type of printed circuit board designed for applications that demand superior heat dissipation and enhanced mechanical strength. Over the years, this technology has become a crucial part of modern electronics, particularly in industries such as LED lighting, automotive, telecommunications, and industrial equipment — all of which rely on efficient thermal management for performance and reliability.

What Is a Metal Core PCB?

A Metal Core PCB differs from a traditional FR4 circuit board by featuring a metallic base layer, typically made of aluminium or copper. This metal core acts as a built-in heat sink, efficiently transferring heat away from high-power components.

In standard PCBs, heat tends to build up within the insulating material, leading to thermal stress, reduced performance, or even component failure. However, in a Metal Core PCB, the metal substrate helps minimise thermal resistance, ensuring that heat is quickly conducted away from sensitive components. This design allows for more stable operation and a longer product lifespan.

Structure of a Metal Core PCB

A Metal Core PCB generally consists of three primary layers:

- Copper Circuit Layer: The top layer, which carries the electrical signals. The copper thickness can vary depending on the current-carrying requirements of the circuit.

- Dielectric Layer: This is an insulating but thermally conductive material that separates the copper circuitry from the metal core. It must provide both electrical insulation and excellent heat transfer.

- Metal Base Layer: The metal substrate forms the foundation of the PCB, most commonly made from aluminium or copper. It serves as the main path for heat dissipation.

In some designs, materials like stainless steel or special metal alloys may be used for enhanced mechanical strength or specific performance needs.

Why Choose a Metal Core PCB?

The Metal Core PCB is ideal for high-power and high-heat applications, offering several key benefits:

- Superior heat dissipation: Quickly transfers heat away from critical components, reducing thermal stress and the risk of overheating.

- Improved reliability: Effective thermal control extends component lifespan and ensures consistent performance.

- Dimensional stability: The metal base prevents deformation caused by thermal expansion, maintaining structural integrity.

- Electrical performance stability: Lower operating temperatures minimise resistance changes, ensuring steady electrical characteristics.

Types of Metal Core PCBs

Depending on the application, different types of Metal Core PCBs are used:

- Aluminium Core PCB: The most common type due to its balance between cost, weight, and thermal conductivity. Widely used in LED lighting systems and power modules.

- Copper Core PCB: Offers the best thermal performance but comes at a higher cost. Suitable for very high-power applications such as power converters or automotive control systems.

- Steel Core PCB: Used where mechanical durability is more critical than thermal performance, often in industrial or heavy-duty devices.

Applications of Metal Core PCBs

The versatility and performance of Metal Core PCBs make them suitable for various advanced electronic systems, including:

- LED Lighting: Essential in high-brightness LED modules, where heat management directly affects lifespan and brightness consistency.

- Automotive Electronics: Used in LED headlights, power converters, and engine control systems that operate under extreme conditions.

- Telecommunications: Applied in base stations and RF amplifiers, where high temperatures and power levels are common.

- Industrial Power Systems: Ideal for inverters, voltage regulators, and power control circuits requiring robust heat dissipation.

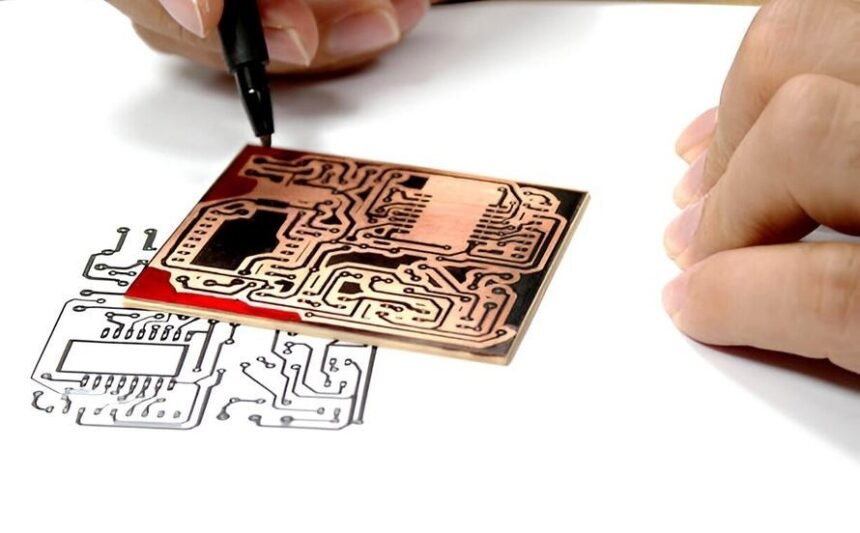

Metal Core PCB Manufacturing Process

Producing a Metal Core PCB involves a series of precise and controlled steps. The process starts with the selection of the metal substrate — aluminium or copper, depending on the application — followed by applying a thermally conductive dielectric layer. The copper foil is then laminated on top, and circuit traces are etched using chemical processing.

After the etching process, solder mask and silkscreen layers are added for component protection and labelling. The final steps include drilling, surface finishing, and thorough testing to ensure there are no electrical shorts and that the PCB meets its required thermal and mechanical specifications.

Economic and Technical Advantages

While Metal Core PCBs tend to cost more upfront compared to traditional FR4 boards, their long-term advantages make them a cost-effective choice for demanding applications. Improved heat dissipation reduces the likelihood of component damage, lowers maintenance costs, and enhances the energy efficiency of the entire system.

Additionally, since components can operate safely at higher power densities, manufacturers can design more compact devices without compromising on reliability. This results in smaller, lighter, and more efficient products — a key advantage in today’s competitive electronics market.

The Future of Metal Core PCBs

As industries continue to shift toward high-performance and compact electronic solutions, the demand for Metal Core PCBs is expected to grow. With the increasing popularity of electric vehicles, smart lighting systems, and renewable energy technologies, manufacturers are relying more on PCBs that can handle high thermal loads while maintaining mechanical stability and performance consistency.

Innovations in dielectric materials and advanced manufacturing techniques are also enhancing the thermal conductivity and design flexibility of MCPCBs, making them even more attractive for next-generation applications.

Conclusion

The Metal Core PCB stands out as the perfect solution for applications that require excellent heat management, structural strength, and reliable performance under demanding conditions. Whether used in LED modules, automotive electronics, or power control systems, MCPCBs ensure stable operation and prolonged component life.

For the best results, partnering with a trusted and experienced PCB Manufacturer in China is essential. Professional manufacturers provide high-quality materials, precision engineering, and advanced production processes that guarantee optimal performance, cost efficiency, and durability. Collaborating with a reliable supplier ensures that your electronic products meet global quality standards and perform flawlessly in real-world applications.