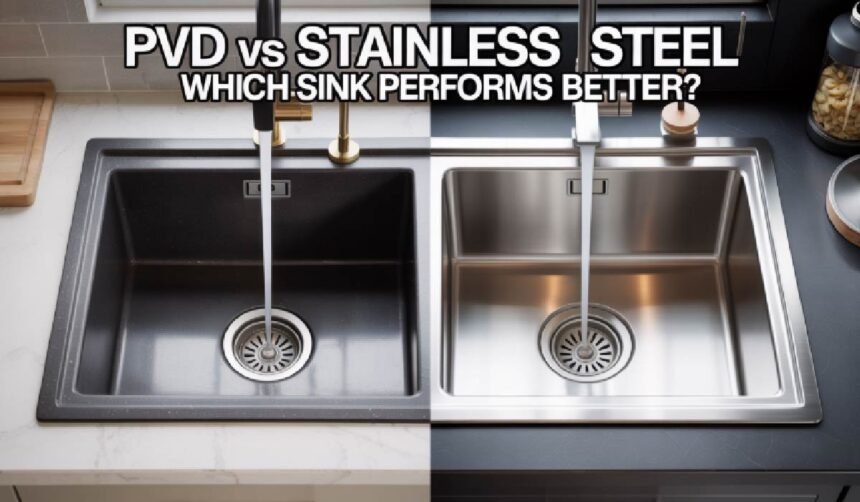

Choosing the right kitchen sink material is more important than many people realize. A sink is one of the most used elements in any kitchen—residential or commercial. It must handle heat, water, heavy cookware, cleaning chemicals, and constant daily use. This is why the comparison of PVD vs stainless steel has become a hot topic in modern kitchen sink manufacturing.

Manufacturers like Aquacubic Faucet Manufacturer work with both traditional stainless steel and advanced surface treatments to meet the growing demand for durability, style, and performance. Understanding how these materials differ helps buyers make smarter, longer-lasting decisions.

Understanding Stainless Steel Kitchen Sinks

Stainless steel kitchen sinks have been the industry standard for decades. They are popular for good reasons: affordability, strength, and resistance to rust.

Most stainless steel sinks are made from steel alloys that contain chromium and nickel. These elements create a protective layer that resists corrosion and staining. This makes stainless steel a reliable choice for everyday kitchens and heavy-use environments.

Key benefits include:

- Strong resistance to rust

- Easy cleaning and maintenance

- Wide availability

- Competitive stainless steel sink cost

However, stainless steel is not perfect. It can scratch over time, show water spots, and sometimes feel noisy when dishes hit the surface. This has led manufacturers to explore surface enhancements like PVD coatings.

What Is the PVD Coating Process?

The PVD coating process (Physical Vapor Deposition) is an advanced surface treatment used to improve durability and appearance. In this process, metal particles are vaporized and bonded to the sink’s surface at a molecular level.

When applied to sinks, PVD creates a thin but extremely hard layer that enhances performance without changing the base material. Many PVD coated sinks are still made from stainless steel, but with a superior surface finish.

PVD coatings are known for:

- Exceptional scratch resistance

- Improved color stability

- Enhanced corrosion protection

- A modern, premium appearance

This technology is widely used in high-end fixtures and commercial environments.

Sink Material Comparison: Performance and Durability

When it comes to durability of kitchen sinks, both materials perform well—but in different ways.

Stainless steel offers:

- Structural strength

- Flexibility under impact

- Long-term reliability

PVD-coated sinks add:

- Extra surface hardness

- Improved corrosion resistance sinks performance

- Better resistance to fading and wear

In daily use, PVD sinks tend to maintain their appearance longer. Scratches are less visible, and the surface feels smoother over time. Stainless steel, while durable, may show signs of wear faster in busy kitchens.

Cost Considerations: Short-Term vs Long-Term Value

Cost is often a deciding factor. Traditional stainless steel sinks usually have a lower upfront price, making them attractive for budget-conscious buyers.

However, when comparing PVD vs stainless steel, long-term value matters. PVD-coated sinks typically cost more initially due to advanced manufacturing and finishing processes. But they often require less maintenance and retain their appearance longer.

For homeowners, this means fewer replacements. For businesses, it means reduced downtime and maintenance expenses—leading to better overall value.

Aesthetic Appeal and Design Flexibility

Design plays a growing role in kitchen decisions. Stainless steel offers a clean, professional look that fits most kitchens. However, it can feel standard or industrial in some spaces.

PVD-coated sinks allow more design flexibility. They come in a variety of finishes, including matte black, brushed gold, and dark gray. These finishes resist fingerprints and discoloration better than traditional coatings.

This makes PVD especially popular in modern kitchens and upscale projects.

Commercial Kitchen Sink Materials: Which Is Better?

In commercial environments, durability and hygiene are top priorities. Commercial kitchen sink materials must withstand heavy use, frequent cleaning, and strict sanitation standards.

Stainless steel remains the most common choice due to its proven performance and lower replacement cost. However, PVD-coated options are increasingly used in premium commercial spaces where aesthetics and longevity matter.

For restaurants, hotels, and catering facilities, the decision often comes down to usage intensity and branding goals.

The Role of OEM and Handmade Manufacturing

Quality manufacturing makes a major difference regardless of material choice. An experienced OEM kitchen sink supplier ensures consistent thickness, precise welding, and proper finishing.

Handmade sinks, in particular, offer advantages in craftsmanship and customization. Working with a reliable handmade kitchen sink supplier allows buyers to choose specific dimensions, finishes, and performance features—especially important for custom kitchens and commercial projects.

Manufacturers that specialize in handmade sinks focus on attention to detail, smooth edges, and durable construction that supports both stainless steel and PVD-coated designs.

Maintenance and Daily Use

Maintenance is another important factor. Stainless steel sinks require regular wiping to avoid water spots and maintain shine. Abrasive cleaners can damage the surface over time.

PVD-coated sinks are easier to maintain. Their hardened surface resists stains, fingerprints, and scratches, making them ideal for busy households and professional kitchens.

Final Thoughts

The choice between PVD vs stainless steel depends on priorities. Stainless steel offers affordability, strength, and proven performance. PVD-coated sinks provide enhanced durability, modern aesthetics, and long-term value.

In today’s evolving kitchen sink manufacturing landscape, both options have their place. For budget-focused projects, stainless steel remains a smart choice. For premium kitchens and high-use environments, PVD-coated sinks offer superior performance and visual appeal.

Ultimately, the best sink is one that balances durability, cost, and design—while being manufactured by a trusted supplier who understands real-world kitchen demands.