In any business or organization, the HVAC systems are pivotal in ensuring air quality, controlling temperatures, and improving efficiency. The choice of HVAC fan usually affects energy usage, reliability of the systems, and performance. The modern solution of PWM fan technology is a modern solution that provides accurate airflow management as well as improved energy efficiency. This article discusses different HVAC fan solutions and their industrial applications, covering the benefits of using PWM fans in a B2B environment.

HVAC Fan Solutions Overview

HVAC fans are relevant in air handling units, chillers, ventilation systems, and in commercial heating and cooling. The fans’ core purpose is to move the air as efficiently as possible to control temperatures, ventilate, and provide environmental comfort. The right choice of a fan improves energy efficiency, reduces maintenance, and prolongs the system’s lifespan.

Industrial decision makers are required to make considerations like the type of fan, system configuration, and control mechanism. With the cumulative adoption of PWM fan technology to support dynamic airflow regulation and improve energy efficiency, modern facilities are becoming smarter. Businesses are increasingly recognizing the operational efficiencies that can be achieved with diverse HVAC fan solutions that support sustainability and cost efficiency, underscoring the growing need to understand the features and characteristics of different HVAC fans.

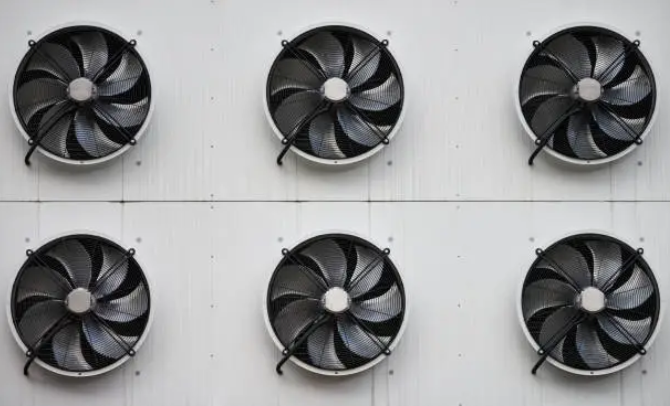

Axial Fans: Airflow of High Volume for Large-scale Spaces

Due to their capacity to shift significant quantities of air along the rotation axis, axial fans rank among the most common HVAC fans. These fans are the best selection for low resistance situations such as freely open areas, ductless ventilation, cooling towers, and equipment enclosures.

Key advantages of axial fans include:

- Optimal airflow efficiency: Circulation of air in large industrial or commercial spaces.

- Space efficiency: Installation on ducts and equipment or in confined spaces is directly done which saves on space.

- Economical choice: Axial fans are simpler in design which results in lower total and ongoing costs compared to other fan types.

With axial fans, permanent magnet motor or PWM fan control allows for fan speed changes to be made dynamically and in accordance to system requirements. These fans are best suited for industrial facilities such as manufacturing plants and commercial buildings. Using PWM control with axial fans enables these facilities to cut on costs and improve air circulation as well as lower operational costs.

Centrifugal Fans: Overcoming Resistance and Enhancing Pressure

Centrifugal or radial fans are capable of producing greater static pressure and thus are used in HVAC systems, filters, and other systems where airflow is limited. Unlike axial fans, centrifugal fans discharge air at a right angle to the rotating axis; hence, they are capable of maintaining airflow across complex duct systems and points of resistance.

Centrifugal HVAC fans also have the following benefits:

- High static pressure output: Perfect for systems with filters and long ducted runs with numerous bends.

- Rugged construction: Built to withstand continuous industrial usage in the demanding environment.

- Flexibility: Able to accommodate air that is dirty or humid.

For B2B industrial applications, integrated Centrifugal fans with PWM (Pulse Width Modulation) fan controls provide accurate airflow control for efficient energy and operational control. These centrifugal fans with PWM controls are commonly used in pharmaceutical, food processing, and chemical manufacturing facilities, which demand tight control of the environment at a minimum energy expenditure.

Advantages of PWM Fan Technology in HVAC Systems

HVAC fan technology has seen great progress with the introduction of PWM fans. These fans operate at different speeds by varying the voltage pulses given to the fan motor. By changing the time the voltage pulses on and off, the fan motor can operate at different speeds to optimize airflow in real time.

Noteworthy advantages of PWM fan inclusion are:

- Energy efficiency: PWM fans use electricity only at the required operational level.

- Minimized mechanical burden: Operating at lower speeds reduces mechanical wear and extends the motor’s operational life.

- Reduced Noise Pollution: Control of the fan’s speed reduces excessive noise associated with fan operation and improves the commercial environments.

- Enhanced control of airflows: The HVAC can be accurately responsive to changing conditions in the environment.

PWM fan technology helps to achieve the sustainability target, and also helps to comply with the set energy efficiency standards in B2B HVAC systems. The use of PWM fans optimizes that cost while ensuring the performance and environmental sustainability of operations.

Analyzing the HVAC Fan Performance

It is necessary to assess the performance metrics in order to select the most applicable HVAC fan solution. The most relevant are:

- Airflow (CFM or m³/h): Axial fans are best for high-volume air movement.

- Static pressure (Pa): The centrifugal fans are better in high resistance or ducted systems.

- Power consumption: The cost of electricity with PWM fan control optimized with speed

- Level of noise (dB): During the low demand operations, the variable speed PWM will reduce noise.

- Service control and reliability: PWM fans have low mechanical wear and maintenance demand.

Knowledge of these performance metrics provides B2B buyers the ability to design HVAC systems that strike the best balance of efficiency, energy consumption, and long-term operational health. The use of traditional fan types combined with PWM technology provides improved control and therefore reduced total cost of ownership.

Considerations with Industrial HVAC Fan Systems

For industrial and commercial HVAC systems, proper fan selection requires the balancing of operational performance, energy efficiency, and environmental impact. Additional factors include:

- System design: Open air or ducted systems, resistance, and spatial constraints.

- Energy efficiency: Ventilation system operational costs, fan selection, and control method.

- Reliability and maintenance: Motor replacement and repair, associated downtime, and long-term durability.

- Noise considerations: Critical for occupied areas and adjacent office spaces.

With the implementation of HVAC fan and PWM technologies, businesses achieve improved airflow management, energy efficiency, and system dependability. As a result, numerous industrial facilities utilize a blend of axial and centrifugal fans controlled by PWM systems to meet high airflow demand while maintaining energy efficiency targets. The proper selection greatly enhances system performance, assists in achieving corporate sustainability goals, and reduces operational costs.

Implementing PWM fans improves HVAC efficiency while simultaneously improving comfort in the workplace, reducing the ecological footprint and operating cost while prolonging the life of the equipment, yielding great ROI for B2B customers.