In maintenance or construction sites a secure access that is not disrupted is important. Road plates come into the picture. These massive steel or composite panels give a fastidious temporary cover over excavations, trenches or loose soil. You will find out the purpose of road plates, their application, how to choose road plates correctly, the safety and the best practice offer and hire choices you have to keep your site open and up to code in this article.

What Are Road Plates?

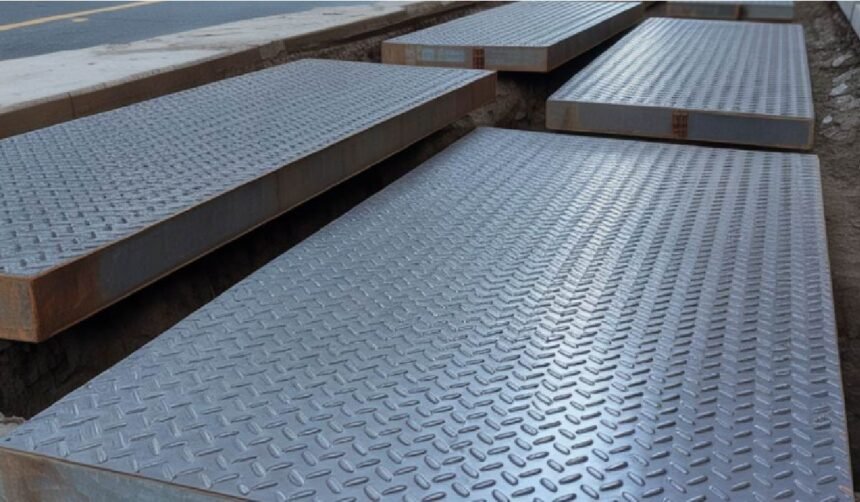

In simple terms, Road Plates refer to huge flat plates, usually of steel, over excavations, trenches or unstable ground so that they form a safe passageway between vehicles and pedestrians. These are commonly deployed in the cases when the temporary cover is needed, or the ground conditions require emergency reduction. The name is a road plate since in the past they were used on the roads and highways to cover the works, but currently it has become widespread in most industries such as utilities, civil engineering and even events.

Benefits of Road Plates

The advantages of using road plates are:

- Improved accessibility to the site: You cover holes or loose soil to enable cars and pedestrians to pass.

- Less disruption: You are able to save the flow of traffic and minimise what has to be closed down and keep the productivity high.

- Cost-effectiveness: Road plates are cheaper to hire out than re-surfacing or permanent solutions, particularly short short-term works.

- Usability: They may be applied in trench cover, crossover point, foot walk or even ground protection in event facilities.

- Safety and compliance: Elevated and installed plates assist in the management of risks and adherence to requirements (e.g. in health and safety legislation).

Ordinary Sizes, Materials and load capacities.

When choosing road plates, it is necessary to be concerned about the size, material and loading capacity. An example of a size that is commonly employed is a 2400 mm x 1200 mm x 18 mm steel plate. This is a size that provides a decent balance between coverage and manageability. Carbon steel is usually used as the material; this is because it is a strong and durable material. The load capacities are different but in some cases, many plates can carry up to a weight of 40 tonnes. Whenever selecting your plate, make sure that it matches the weights, traffic, and site requirements.

How to Select the Right Road Plates on your site.

There are a number of considerations when choosing the right road plate:

- Traffic type and load: Are heavy trucks going to cross this area or will it be light vehicles/pedestrians only?

- Site ground conditions: Soft soil may require more support or more thickness under the plate.

- Size and coverage: The plate should be large enough to cover the entire hazard area, but should have sufficient margins so as not to concentrate the loads along its sides.

- Logistics of installation and removal: Provide lifting holes or anchor points to be handled safely (a lot of the plates include such as a standard).

- Time and employment conditions: Emergency works that can be over a short period might have other conditions compared to infrastructure projects that take several months.

- Compliance and safety considerations: The plate should comply with any applicable standards, be conspicuous, and be installed in accordance with best practices.

Installation Safety Recommendations and Best Practice.

There is no compromise when using road plates. Key points to remember:

- Plates should be firmly fixed on a steady base; otherwise, the surface of the ground beneath may be too soft and cause the plates to move or fall.

- Move heavy plates with mechanical lifting equipment – there are lots of heavy plates.

- Signage and edge protection: There is a need to have a safe transition between vehicles and plate surfaces; look at ramps or traffic control.

- Inspection: Before installation, inspection of plates to be used should be done on deformation, cracks or corrosion and regularly during use.

- Traffic control: When plates are used over live trafficways, provision should be made to close the roads, markings and safe working areas in accordance with local rules (e.g. highway authority regulations).

- Cable / service voids: In some cases, plates are used to cover the area over which underground works in progress are taking place – lifting holes must allow accessibility and personnel must be aware of dangers underneath the plate.

Which is better, purchasing or hiring Road Plates?

In most of the projects, the Road Plates are the viable option. Benefits of hiring include:

- Reduced initial expenditure: You do not have to spend a lot of money upfront, particularly on one-off or short-term projects.

- Available on short notice: Hire firms typically have massive fleets and are fast. Indicatively, some specialists offer next-day delivery.

- Flexibility: Plates can be returned when not required and numbers changed in case the scope varies.

Purchasing can be reasonable when it is a long-term and frequent use, or in case your organisation possesses storage and maintenance. However, in the case of most temporary jobs, hiring is very effective.

Common uses of Road plates.

The road plates are applicable in broad situations:

- Utility and drainage works – include water, gas, telecoms or cables trenches.

- Civil engineering and groundworks – allowing access to machinery on soft or disturbed ground.

- Events and temporary installations – the development of routes through grass, gravel or temporary materials by pedestrians or vehicles.

- Emergency works – excavations around excavations and reinstatement (where quick access is required) or delayed reinstatement.

- Traffic control – the opening up of the road and maintaining constant movement safely through providing stable crossing points and covering openings.

Price Factors and Value-Based Money.

Although prices differ in size, material, time and place, the worth of proper road plates is obvious. You can be productive instead of closing the doors, redirecting the traffic or repairing surfaces. Other providers provide standard weekly hire rates of a 2,400 x 1,200 x 18 mm plate at a rate of as low as approximately £15 a week. Include factors in deposit, delivery/collection costs and minimum hire period. Include labour and site traffic management, or any ramping or edge transition works, as needed when budgeting.

Conclusion

Summing up, road plates are a safe, simple and cost-efficient way to cover excavations, stabilise soft ground, and ensure the traffic movement and movement of pedestrians around the area. The correct choice of size, material and hire set-up and proper installation taking safety and logistical factors into account will ensure that your project is on schedule, on budget and meets the health and safety requirements. Road plates should be included on your list of planning requirements whether you are performing utility maintenance, a major building development or temporary event installation. Contact a reputable hire company today and clearly state your requirements on the type of plate to be hired out so as to end up with the right plate that suits the job.