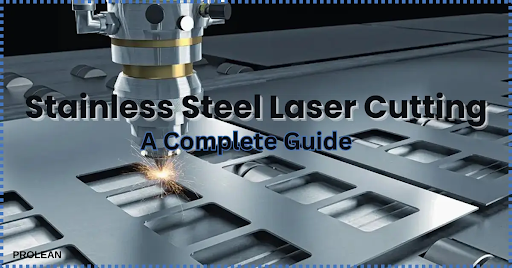

Stainless steel laser cutting ensures manufacturers achieve accurate cuts, clean finishes, and a faster production cycle. Laser technology has changed the way businesses work with metals. Stainless steel is one of the most versatile materials. It is known for its strength, durability, and visual appeal.

This article discusses the method, suitable stainless steel kinds, and how the optimal stainless steel laser cutting service provides precision and quality in a variety of applications.

What is Stainless Steel?

Stainless steel refers to a group of several alloy types like austenitic, ferritic, martensitic, precipitation-hardening, and duplex (a mix of austenitic and martensitic). Each alloy mainly includes iron, carbon, and chromium, along with other metals like nickel, molybdenum, copper, niobium, titanium, and aluminum.

Precision Laser Cutting Process on Stainless Steel Sheet

Nonmetallic components like silicon, carbon, and sulfur are also added. Different alloy compositions produce distinct qualities. Some stainless steels are very magnetic, whereas others are weak or nonmagnetic. Certain types harden quickly, while others stay soft. Stainless steel is well-known for its corrosion resistance, but not all kinds perform equally well. It’s a significant consideration when selecting materials for stainless steel laser cutting applications.

What are the Best Stainless Steel Grades for Laser Cutting?

The best stainless steel grades for laser cutting are austenitic (300 series), martensitic (400 series), and ferritic (430 grade) stainless steel. These primary dominating stainless steel grades are acceptable for laser cutting:

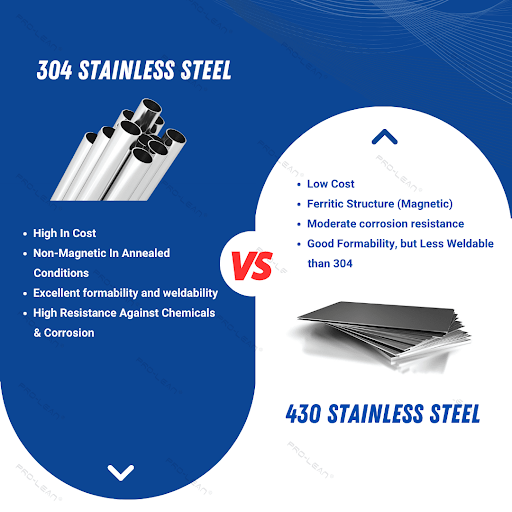

1. Austenitic Stainless Steel (300 Series)

Laser cutting 316 stainless steel is common because austenitic grades like 304 and 316 are nonmagnetic and highly resistant to corrosion. They have a high nickel and chromium concentration, making them suitable for ornamental panels, enclosures, and food-grade components.

These grades are prone to work hardening during machining, but stainless steel laser cutting eliminates this with precise heat control.

2. Martensitic Stainless Steel (400 Series)

Martensitic grades can be strengthened by heat treatment, providing high wear resistance and strength. Despite their lower corrosion resistance, their machinability makes them ideal for laser cutting stainless steel products such as blades and industrial equipment.

3. Ferritic Stainless Steel (430 Grade)

Ferritic stainless steels have a body-centered cubic structure and exhibit excellent thermal conductivity. They are magnetic and commonly utilized for ornamental purposes. While weldability is restricted, they work well for custom laser-cut stainless steel applications with clean, defined forms.

304 VS 430 Stainless Steel

What Types of Lasers Are Used in Stainless Steel Cutting?

Fiber lasers and CO₂ lasers are the two main types of lasers used in stainless steel cutting. Fiber lasers are the best choice for custom stainless steel laser cutting in most applications because they provide faster, more efficient, and more precise results. CO₂ lasers are useful for applications that demand deep cuts and long-lasting performance at a reduced initial cost.

Fiber Laser Cutting for Stainless Steel

Fiber lasers are the best choice for stainless steel laser cutting due to their speed, accuracy, and energy efficiency. These lasers provide a narrow, focused beam, about half the width of a CO₂ laser, resulting in more cutting power with the same energy. The end effect is cleaner edges, higher accuracy, and faster manufacturing times.

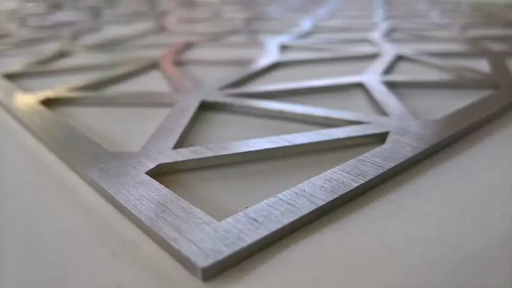

Custom Laser Cut Stainless Steel Panel with Clean Edges

They are also low-maintenance and cost-effective, although they require additional nitrogen gas for shielding. Overall, fiber lasers are the finest option for custom laser cutting stainless steel parts, since they provide an exceptional polish and precision with each cut.

CO₂ Laser Cutting for Thicker Stainless Steel

CO₂ lasers are a viable alternative for cutting stainless steel, especially thicker materials that do not require high accuracy. They provide a wider beam (about 600 µm), allowing for high-power cutting of tough components.

CO₂ laser machines are less expensive initially than fiber lasers, but have higher operational expenses due to increased energy consumption and maintenance requirements.

What are the Tips for High-Quality Stainless Steel Laser Cutting?

Achieving flawless outcomes necessitates both the proper tools and techniques. Professionals providing stainless steel laser cutting services use the following practices:

- Set the assist gas appropriately to avoid splashback and oxidation.

- To get the best kerf width, adjust the focal depth based on material thickness.

- Keep the lenses clean to ensure constant beam quality.

- Inspect the nitrogen gas flow to prevent discolouration and oxidation.

- Monitor heat-affected zones (HAZ) and adjust power or speed as necessary.

- Begin with the recommended settings and fine-tune gradually based on test cuts.

By following these guidelines, producers can obtain smooth, consistent, and visually acceptable outcomes.

Applications of Custom Laser-Cut Stainless Steel

The possibilities for custom laser-cut stainless steel are virtually limitless. This method is utilized in:

- Industrial fabrication includes machined pieces, coverings, and precise brackets.

- Architectural design includes railings, signs, and ornamental panels.

- Consumer items include kitchen appliances, lights, and metal art.

- Medical and food industries components that must be hygienic and corrosion-resistant.

Laser cutting allows for high repeatability in the production of intricate perforations and complicated designs.

How to Laser Cut Stainless Steel Efficiently

- Use a fiber or CO₂ laser with the appropriate power for the material thickness.

- Adjust the focal length, power, and speed settings precisely.

- Use nitrogen assist gas to get clean, oxidation-free edges.

- Do test runs on scrap before final manufacture.

- Secure the stainless steel sheet correctly to avoid vibration.

Following these instructions will result in consistent, professional-quality stainless steel laser cutting every time.

Advantages of Stainless Steel Laser Cutting Services

Stainless steel laser cutting has many advantages over traditional mechanical cutting or CNC machining methods, including faster output, less contamination of the workpiece, and a lower risk of warping. A laser cutter creates clean laser-cut items with a low likelihood of operator mistakes, making them ideal for rapid prototyping.

Precision Stainless Steel Components from Laser Cutting Services

ProleanTech’s stainless steel laser cutting services provide a cost-effective on-demand solution for your sheet metal manufacturing needs, regardless of the material, intricacy, or project size. From low-volume prototypes to high-volume production runs, Prolean’s extensive partner network has the right shop and tools for the task.

Conclusion: Precision Meets Performance

Stainless steel laser cutting has transformed modern metal manufacturing. It uses fiber or CO₂ lasers to create clean edges with high repeatability. It provides unmatched quality for all industries because of its clean edges, minimal distortion, and high speed. Working with a skilled stainless steel laser cutting service guarantees dependability and perfection from custom laser-cut stainless steel components to large-scale production runs.

From delicate art pieces to industrial-grade components, laser cutting SS technology is shaping the future of manufacturing, one flawless cut at a time.