In today’s fast world, every business wants to save time and money. In the metal industry, laser pipe cutting is already a smart way to cut pipes with speed and accuracy. But now, with automatic loading and unloading systems, pipe cutting has become even better.

These systems help workers do less manual work. Machines can load and unload pipes by themselves. This helps companies save time, reduce mistakes, and cut more pipes in less time. In this article, we will talk about the advantages of automatic pipe cutting systems and how they can help your business.

What Is Automatic Loading and Unloading?

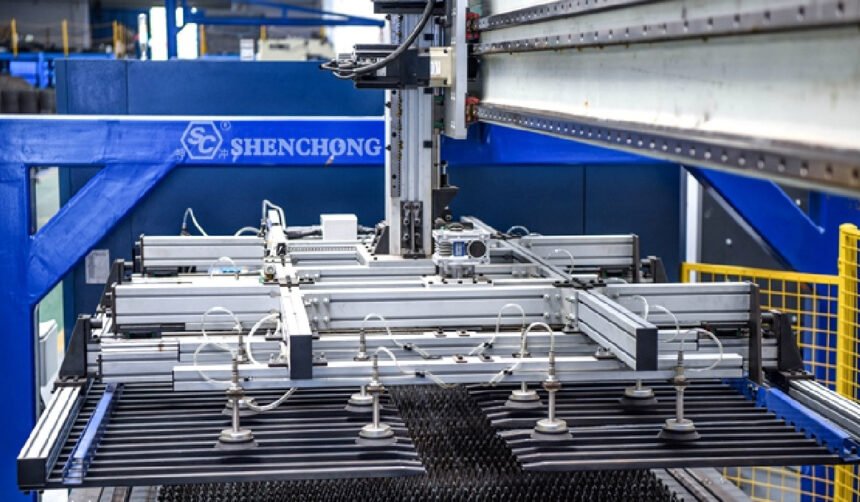

Automatic loading and unloading means the machine picks up and places the pipe independently. Once the cutting job is done, the machine also removes the finished pipe. Workers don’t need to lift or move heavy pipes.

Everything is done smoothly and safely by the machine. This is very helpful when cutting many pipes or working with long and heavy materials.

1. Faster Cutting Jobs

One of the biggest advantages of automatic pipe cutting systems is speed. With manual work, each pipe takes time to place and remove. Workers may also get tired or make mistakes.

With automation, the machine does the loading and unloading very fast. This reduces the total time needed for each job. You can cut more pipes every day without rushing your team.

2. Less Labor, More Savings

Hiring many workers to lift and move pipes costs money. But when you use automatic systems, you need fewer people. This means lower labor costs.

In addition, your present-day group may be cognizant of different essential jobs, which include great management or system control. Finally, you save time and money.

3. More Safety for Workers

Working with heavy pipes can be risky. Lifting or moving large pipes by hand can cause injuries. Automation removes this risk.

The machine handles the heavy lifting, so workers stay safe. This reduces accidents at work and keeps your team healthy.

4. Better Accuracy

Manual loading can sometimes cause misalignment. If the pipe is not placed correctly, the cut will not be clean and precise. This means you may waste material or need to redo the job.

Automatic systems are smart. They place the pipe exactly in the right position. This helps you get clean, precise cuts every time.

5. Less Material Waste

Good accuracy also means less waste. You don’t lose money on wrongly cut pipes. The machine knows exactly where and how to cut.

This helps you use every piece of pipe properly, saving materials and money.

6. More Production in Less Time

With automatic systems, you can cut more pipes in less time. You don’t need to stop the machine to load or unload by hand.

This means your production line runs non-stop. You can take more orders and finish them faster.

7. Easy to Use with Software

These systems work well with computer programs. You just upload the design file, and the machine does the rest. It loads the pipe, cuts it, and removes it – all without human help.

This makes the whole process easy and smooth. Your team can learn to run the system in very little time.

8. Great for Big and Small Jobs

Whether you have 10 pipes or one thousand, computerized loading and unloading structures are useful. They assist you with shopping and continue to work without breaks.

For huge jobs, they provide you with the speed you want. For small jobs, they help you work more quickly with fewer people.

9. Stronger Business Growth

When the cut is sharp, clean, and secure, more clients will depend upon your work. You can quickly supply jobs, take larger orders, and grow your business.

Using modern technology, such as automated pipe cutting systems, gives you a bonus over your competitors.

10. Perfect for Modern Factories

Many factories today want to become “smart factories.” This means using machines and automation to do most of the work.

Automatic loading and unloading is a big part of this. It helps you move to smart production with fewer errors, less waste, and better results.

Example: How a Company Saved Time with Automation

Let’s say a company cuts metal pipes for furniture. Before using automatic systems, they had five workers just for lifting and placing pipes. Each job took many hours.

After they switched to an automatic system, the job time was cut in half. They needed fewer workers, and they made more pipes every day. Customers were happy with fast delivery, and the company earned more profit.

Want to Know More? Contact DOWELL Laser

If you are geared up to improve your manufacturing unit and experience the advantages of computerized pipe sugar structures, we can help. To learn about our clever machines, contact Dowel Laser and see how they can assist your enterprise.

We offer powerful, reliable, and easy-to-use laser tube slicing machines with automated functions. Our group will guide you and help select a high-quality solution to meet your needs.

Conclusion

Automatic loading and unloading structures alter how pipe cutting works. They make the activity fast, secure, and clean. Your team works higher. Your factory becomes more efficient. And your customers get fast transport.

In short, the advantages of automatic pipe slicing structures are greater. They help shop time, cut expenses, and boost your enterprise. If you need to stay beforehand in the latest marketplace, the time is to put money into automation.

Don’t wait; permit the machines to do the work so your crew can focus on more. Upgrade nowadays and take your business to the next level.

You May Read Also: Traceloans.com Student Loans: Smart, Stress-Free Borrowing